Integrating CNC and 3D modeling into the production process of Tampa Bay businesses since 2015

HOW DOES IT WORK

- We 3D model and prototype components, then produce them for you on demand, with short lead time, and no minimum quantity

- We create fixtures to cost-effectively integrate the components into your unique production setting, reducing your labor cost

- We offer solutions to optimize material use and reduce your cost per part

- We offer an array of secondary operations, as well as local delivery and drop shipping

Do you want the benefit from CNC-cut, 3D-modeled components without the expense of a CNC or engineering department?

We work every day with Tampa Bay area business owners, effectively providing them with an on-demand CNC & Engineering department . We are located in Tarpon Springs, Florida and more than 80% of our business is within Pinellas County.

Give us a call to know how your can get free setup and design, by rolling back these fees into production costs

Is your production held up by components that require excessive time and focus from your production crew?

HOW DOES IT APPLY TO YOUR BUSINESS

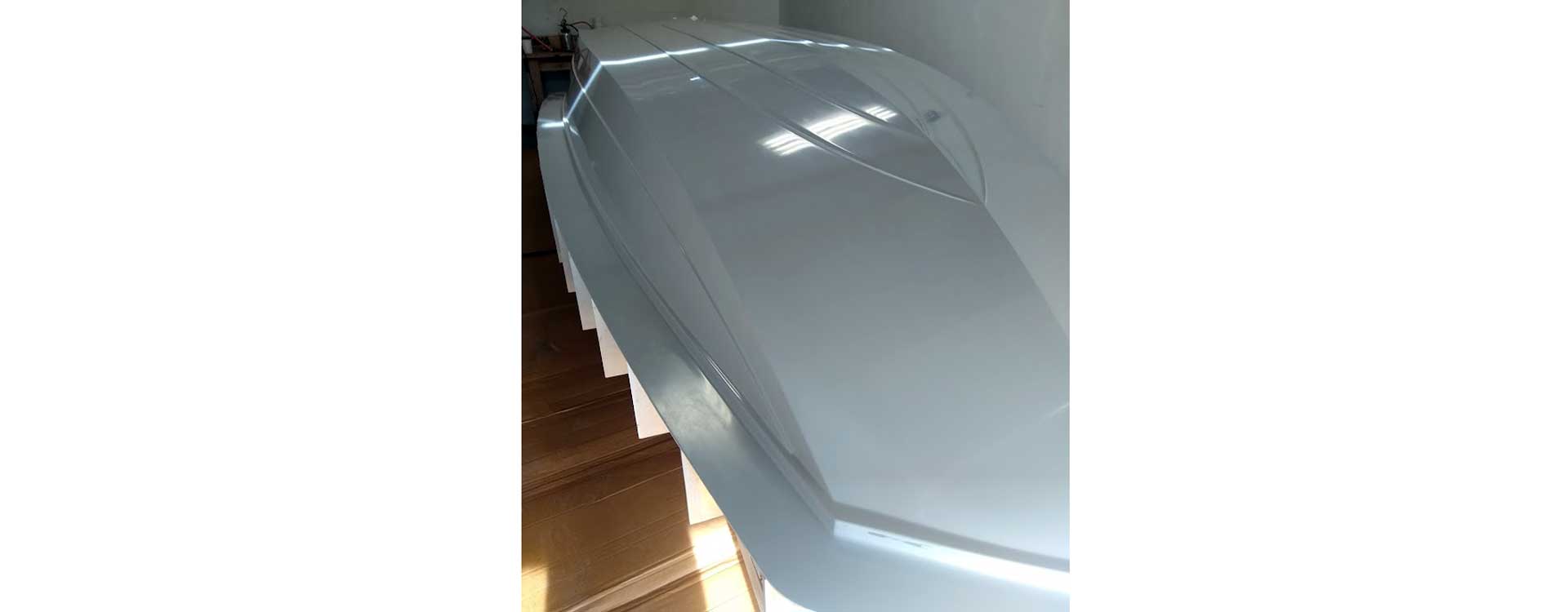

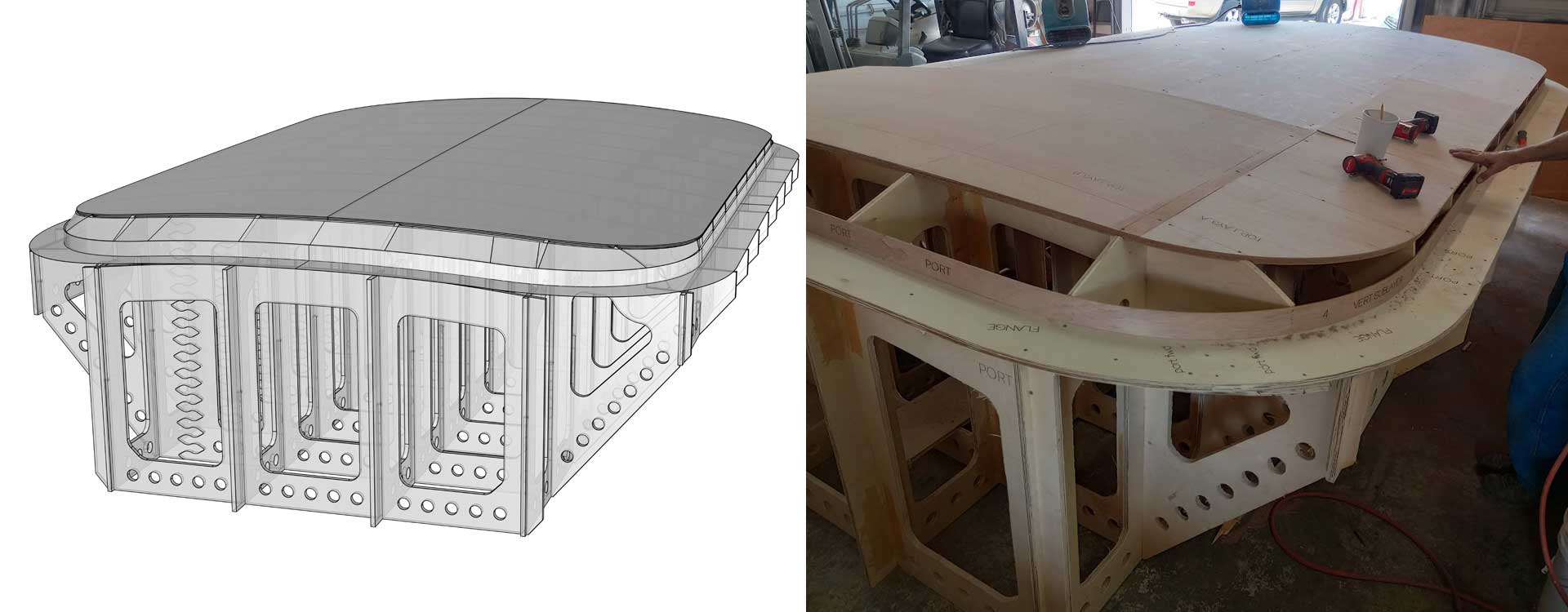

OEM Boatbuilders

Our in house tooling department can create plugs, molds and parts from your 3D model, drawing or splash. We can create Coosa transom and stringer kits and Starboard components. Our CNC capabilities include two tables with tool changer and vacuum, as well as a new-to-us and not yet installed 5-axis with a cutting envelope of 22.5’L x 10.5’W x 8’H. We will work in close collaboration with your designer or engineering department to produce accurate parts on time.

OEM Manufacturers

We carry and have extensive experience CNC machining plywood, MDF, HDPE, acrylic, and PVC sheet goods, using fixtures and vacuum. We offer secondary drilling and rounding over, and these can then be loaded on pallets and delivered by courrier or LTL to your facility. Lead time is rarely over a week once production is setup, and often can be accommodated within 24 hours for urgent items

Marine Designers

We can turn your design into a boatbuilder-ready strongback kit whether they are a professional or amateur. We can integrate permanent components of marine plywood, Coosa, foam core and/or dimension lumber into a strongback of temporary MDF or birch plywood. Parts ID and notes to builder plotted on the actual parts, drop shipped to your customer on a pallet via LTL or courrier.

Sign Shops

Send us a PDF and we’ll turn it into a Bebond back, offset and cut the acrylic face to create the perfect can every time and save labor on your end. Delivered to your shop.